Pro AV News and Tech Tips

Our blog is dedicated to bringing you the lastest information related to the audio, video, presentation technologies and the people who love them.

12 minutes reading time

(2461 words)

Installing Hearing Loop Systems & Costing Application Note

Description

This document will address various factors contributing to the total installed cost of various examples of Hearing Loop system and the importance of the information a properly completed Clarification Form provides in creating an effective design.

AFILS (Audio Frequency Induction Loop Systems) aka Hearing Loops, can present challenges to a contractor/integrator in establishing a ballpark price upon which a client is able to make a decision. Critical installation factors can change the installed cost of a system by a factor of 2 –to- 5 times.

Installation Factors

In order to determine the correct system configuration for a particular application, it is essential that certain measurements are made at the venue. One of the first steps to take on a job site is to measure for any magnetic background noise for the intended hearing loop installation. Ideally, all electrical systems should be on while testing for magnetic background noise (Note: This step may not be possible as in new construction sites). This measurement of magnetic background noise is crucial to establish that a usable signal-to-noise ratio that can be achieved in the final system. After this is done, the contractor can continue with running a known quantity “Test Loop(s).” After running a simple Perimeter/Rectangular or Figure-8 wire shape is laid out, a measurement of the current input to the test loop is compared to the strength of the field generated, giving the designer an understanding of the test

environment where, for example, magnetic field generation is suppressed by metal structures in the building. These results give the Listen Tech designer data around which a design can be formulated.

The specifying and costing for this type of basic system will include taking these measurements, 300 ft (91.44 m) to 600 ft (182.88 m) of single conductor loop wire, and an induction loop amplifier, known as a loop driver, a FSM (Field Strength Meter) and the labor to install and commission this hardware.

350 ft (106.68 m) of loop wire will cost between $100-$140 MSRP (depending upon AWG 16 or, 14 AWG) and single loop drivers range from $650 to $2,100 MSRP depending on the loop current needed. For our trained and certified Level 2 partners, we offer a complete Hearing Loop Test Kit with all of the essential equipment.

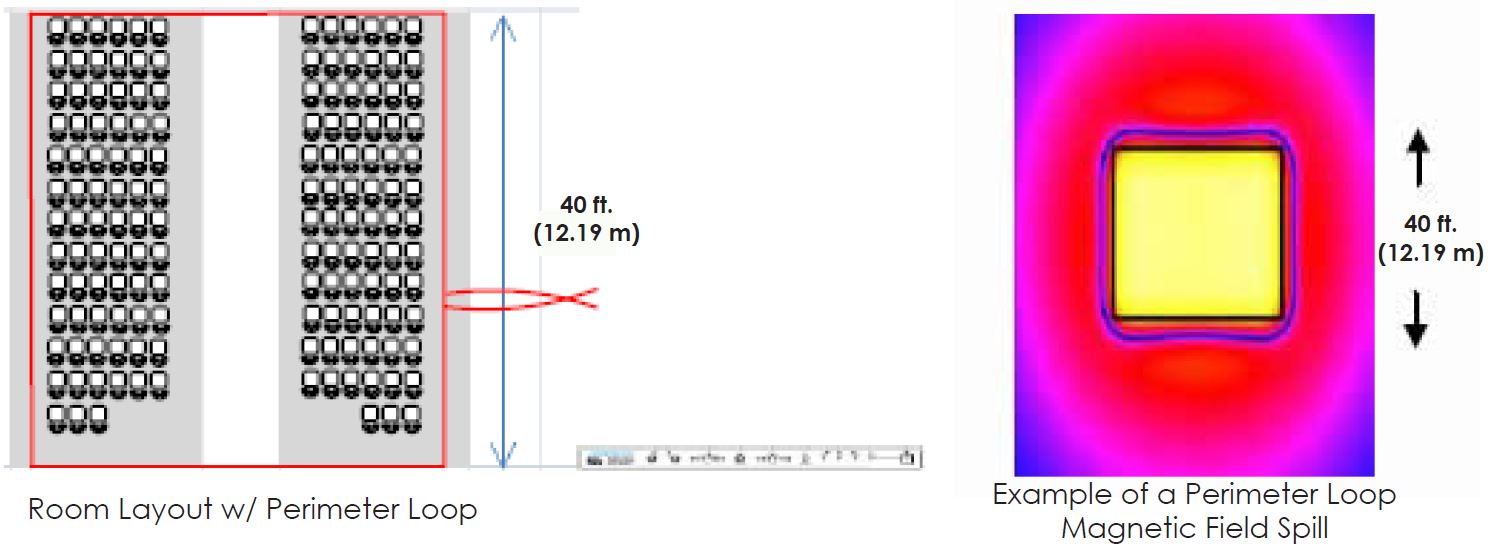

The physical size of the area to be installed is a key element as to what type of loop layout can be utilized. Typically, if you have a room within the dimensions of approximately 45 ft. (13.72 m) x 45 ft. (13.72 m) or less and there is no metal in the structure or, other concerns, a simple Perimeter Loop may be possible. Installation areas larger than the dimensions mentioned above or, if there is any metal involved; typically mean some form of a more complex system like a phased array will need to be designed for this space.

Listen accesses decades of experience over many thousands of installations and specialized software and CAD to provide a design service to its trained and certified contractor partners. There is a nominal charge for this service. See the associated systems costing following.

Seems pretty straightforward? It is. However, there are a number of variables that need to be understood to make a workable cost projection/estimate.

Labor is one factor that can radically affect systems pricing. On a new construction project, where, for example, there is no metal loss to overcome, an installer (or, installers) can lay down the wire or, flat copper tape, before the carpet and floor coverings are installed, in two to six hours.

When installing in existing spaces where one has to work with installed floor coverings, pulling up carpet can be expensive and involve hidden costs and risks. Sometimes laying the wire or copper tape under a carpet is not an option and concrete may need to be sawn to make a small trough in which to sink the wire in and then back- fill and refinish. Depending upon local concrete contractors, concrete sawing can cost anywhere from $2 - $10 per ft. (m), or more.

Occasionally an installation is required where the floor cannot be touched, for example a traditional church with intricate marble flooring. In these circumstances alternative methods must be used.

*Note: Many contractors find it expedient and less risky for the client to contract the carpet or flooring company directly. Keeping this area of expense, detail and specialization clear of the sound systems contract. The liabilities and aesthetic issues that often arise during the removal and replacement of carpet hardwood and other potentially precious flooring, can be significant and expensive.

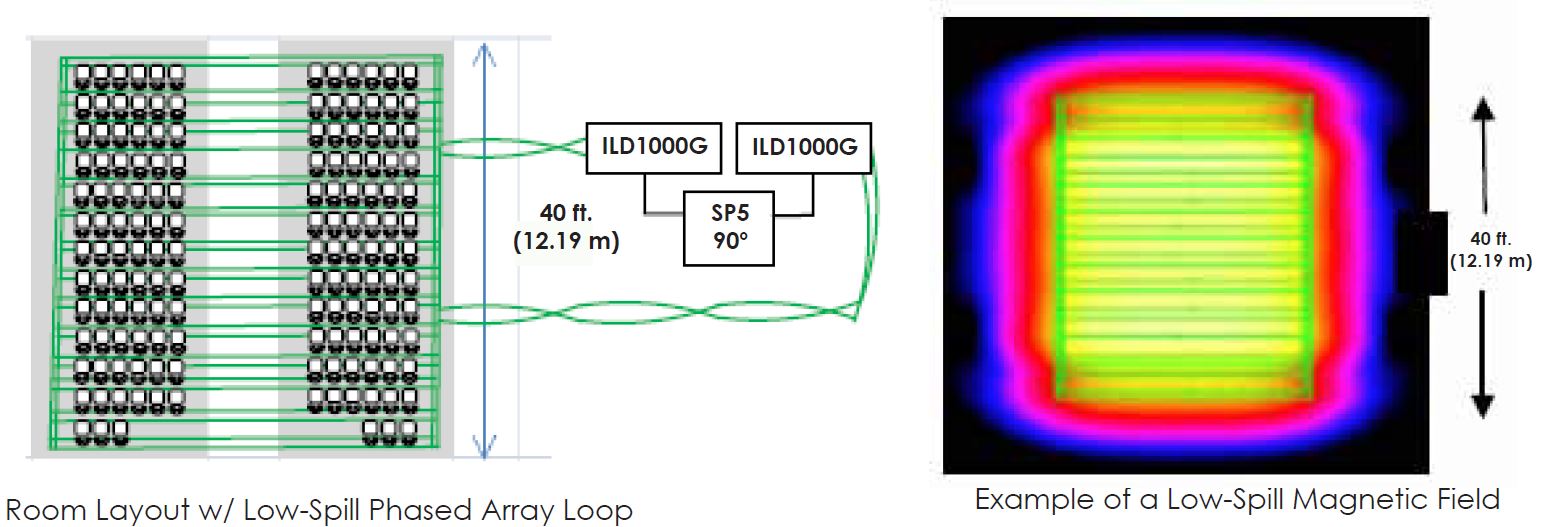

If testing indicates there is some form of metal in the construction, a more complex design may be required to overcome the loss of field strength the metal can cause. The design used to overcome these losses is known as a “Loss Control Phased Array Loop” which will require dual loop drivers, a 90º audio phase shifter and specialized loop wire layout configurations. Since these phased array type systems involve the entire floor area, removal of carpet is mandatory as opposed to a perimeter loop which can sometimes be installed by rolling back a carpet’s outer edges.

Another factor that needs to be established with the client is whether or not multiple rooms will either be immediately or, at some time in the future need to be looped. Since simple perimeter loops radiate fields 2-to-3 times the width of their size, adjacent rooms would have audio crosstalk and interfere with each other unless another type of loop design is used: Spill Control Phased Array Loop. These, like the Loss Control designs have a greater cost in equipment and installation, labor, etc.

Other items to consider are the routing of the source audio to the loop driver. This will vary as your source may come from a simple direct microphone, to a more complex system with an audio console. In some installations, you may have the additional cost of configuring a DSP audio device with processing to feed your system input.

To establish a high standard for performance of these systems Listen Technologies uses the IEC 60118-4 standard for Hearing Loop systems. This international standard takes into account background noise, the correct and consistent field strength, the volume of use of the installation space, even field coverage and consistency of frequency response.

Lastly, you would want to ensure that you include some time to train the client in all aspects of the system use, signage and potentially periodic maintenance system checks.

On the following pages, we will give you a guide for typical “classic” Loop Systems we will describe two different scenarios for a small sized church, and two different scenarios for a performing arts center. The first example will describe an installation with no serious issues to contend with compared to a more complex installation in the same theoretical venue.

#1 Traditional Church (simple wooden structure)

Dimensions are 40 ft. (12.19 m) x 40 ft. (12.19 m). 150 seats with standard pews or chairs, with one central aisle and aisles on each side.

The initial Test Loop and measurements indicated very low magnetic background noise and no structural metal issues, with no adjacent rooms to consider for future loop installations. Flat copper tape was chosen since it installs invisibly under the carpet. Special PWT protective self adhesive tape is used to secure the copper tape to the floor. The carpet is re-installed on top.

A Simple Perimeter Loop installation Cost Guideline

*Estimated Initial loop testing $ 250.00

(*Note: Determined by Dealer to include travel, hours, test equipment, etc.)

LA-30 Basic Design Charge $ 399.00 (MSRP)

164 ft. (49.98 m) of FB1.8 Flat Copper Tape $ 144.00 (MSRP)

30 ft. (9.144 m) of 14 AWG Feeder Cable $ 12.00 (MSRP)

164 ft. (49.98 m) of PWT Warning Tape $ 98.00 (MSRP)

ILD500 Loop Driver $1,499.00 (MSRP)

Labor (*$100/hour per technician *Note: To be determined by contractor/installer)

• Four (4) hours to lay the Flat Copper Tape and feeder cables from equipment rack.

• One (1) hour to solder and terminate the feeder cable and interconnect.

• One (1) hour to calibrate and commission the system.

Total Labor $ 600.00

#1 Total System Cost $3,002.00

#2 New Church (newer contemporary structure)

Dimensions are 40 ft. (12.19 m) x 40 ft. (12.19 m). 150 seats with standard pews or chairs, with one central

aisle and aisles on each side.

The Test Loop indicated measurable metal loss as well as there being adjacent classrooms that will require future loop installations. The need for both metal loss compensation and spill control mandate the use of a Low-Spill Phased Array type design. The church intends to use a stained-polished concrete floor finish, requiring the cutting a small ½” wide, by ½’ deep saw cut-trough in which to install the 14 AWG loop wire and then filling with concrete or other filler.

A Low-Spill Phased Array Loop Installation Cost Guideline

*Estimated Initial loop testing $ 250.00

*Note: Determined by Dealer.

LA-31 Advanced Design Charge $ 795.00 (MSRP)

1080 ft. (329.18 m) of 14 AWG Loop Cable $ 421.20 (MSRP)

60 ft. (18.28 m) of 14 AWG Feeder Cable $ 24.00 (MSRP)

A1000G-RM Phased Array Kit $4,901.00 (MSRP)

1080 (329.18 m) estimated concrete cutting $3,240.00

(Costs vary significantly from State to State / Estimated at $3 per ft. (m))

Labor (*$100/hour per technician) *Note: Determined by Dealer

• Six (6) hours to lay the wire

• Six (6) hours to fill the tough* *Note: This work may be sub-contracted

• Six (6) hours to sand and finish* *Note: This work may be sub-contracted

• One (1) hour to solder the feeder cable and interconnect

• Two (2) hours to calibrate and commission the system

Total Labor $2,100.00

#2 Total System Cost $11,731.20

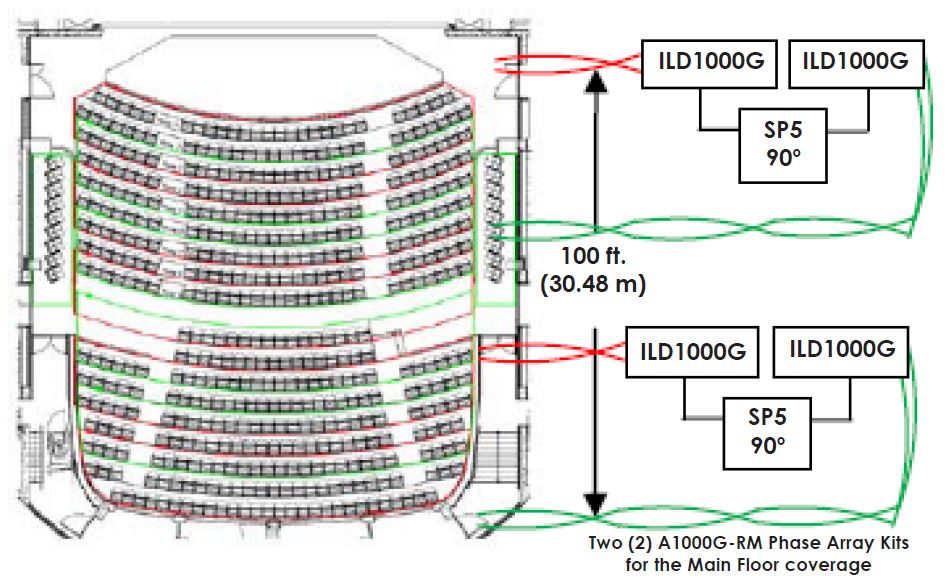

#3 Performing Arts Center (simple)

1000 capacity with standard theatre seating, with two box areas and one balcony. Only the main floor was needed to be covered by the loop. The two box areas and balcony are not covered.

The initial Test Loop indicated no metal loss issues, there are no adjacent rooms to consider. Due to the large physical size of the space, and for even coverage a perimeter loop wasn’t chosen, and two phased array systems were selected for this installation. The wire chosen was a flat copper tape with its low profile under carpet, with special PWT tape. The venue decided not to loop the two boxes and the balcony.

Main Floor Phased Array Loop Installation Cost Guideline

Initial loop testing $ 500.00

The large main floor area only, 2 large loops.

LA-31 Advanced Design Charge $ 795.00 (MSRP)

Thirty-One (31) Rolls of FB1.8 Flat Copper Tape $4,464.00 (MSRP)

Thirty-One (31) Rolls of PWT Tape $3,038.00 (MSRP)

Two (2) ea A1000G-RM Phased Array Kits $9,802.00

(*$4,901.00 (MSRP *Each) Two for the main floor)

Labor (*$100/hour per technician)

*Note: Determined by Dealer

• Seven (7) hours to lay the FB1.8 Flat Copper Tape & PWT

• Three (3) hours to solder the feeder cable and interconnect

• Three (3) hours to calibrate and commission the system

Total Labor $1,300.00

#3 Total System Cost $19,899.00

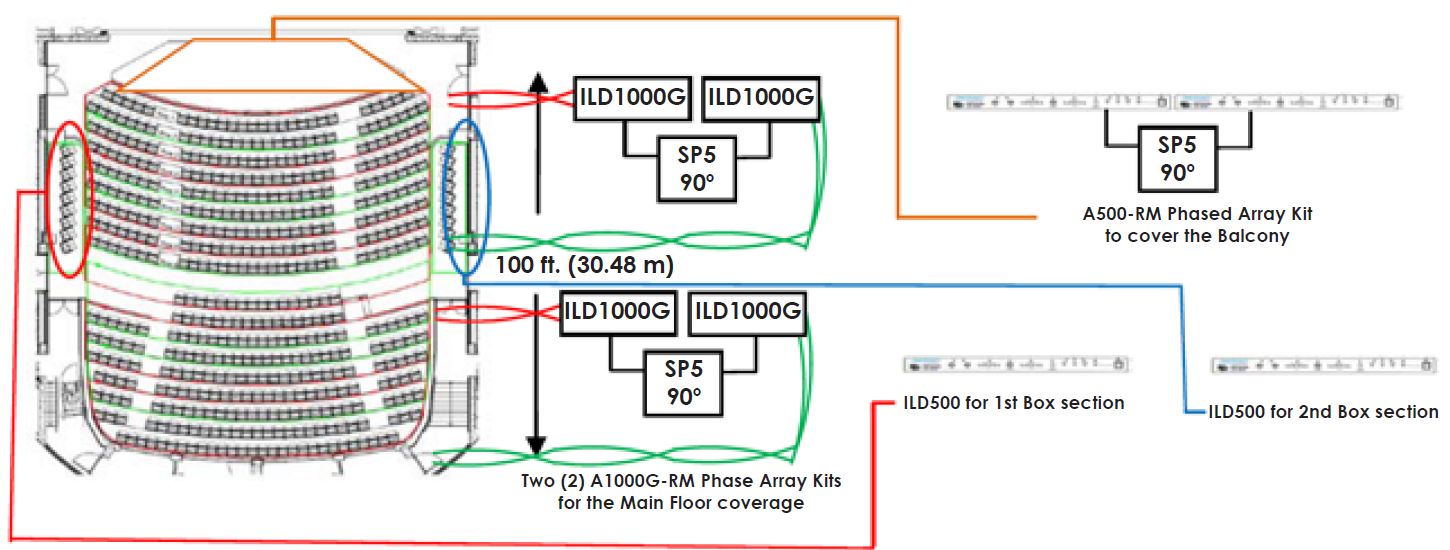

#4 Performing Arts Center (with installation issues)

1000 capacity, with standard theatre seating, two box areas and one balcony

The initial Test Loop indicated metal loss, but no adjacent future installation rooms. The wire chosen will be standard 16 AWG buried in the concrete floor, requiring the cutting of a small ½” by ½’ deep trough, installing the wire and then filling with concrete filler.

Main Floor, Two Boxes and Balcony Phased Array Loop Installation Cost Guideline

Initial loop testing $ 1,000.00

(Four (4) tests, balcony, main floor, and each box)

LA-31 Advanced Design Fees $ 1,590.00

(Qty. of Two (2) Advanced Design Fees)

6000 ft. (1828.8 m) of 16 AWG wire $ 1,680.00

Two (2) each A1000G-RM Phased Array Kits $ 9,802.00

(*$4,901.00 (MSRP *Each) Two (2) for the main floor)

One (1) A500-RM Phased Array Kit $ 3,701.00

(For the balcony section)

Two (2) ILD500 Loop Drivers $ 2,988.00

$ 1,499.00 (MSRP *Each)

(One (1) each for the box sections)

• 6,000 ft. (1828.8 m) of concrete cutting $18,000.00

(*Estimate only of $3 per ft. (m) see local costs)

Labor (*$100/hour per technician) *Note: Determined by Dealer

• Twelve (12) hours to lay the wire

• Ten (10) hours to fill the tough

• Ten (10) hours to sand and finish

• Six (6) hours to solder the feeder cable and interconnect

• Eight (8) hours to calibrate the system

Total Labor $ 4,600.00

#4 Total System Cost $43,371.00

In Conclusion

Clearly both of the church System 1 and System 2 are essentially the same size churches, but for the second church example, because of environmental issues (metal loss), and the need to control the spill to allow additional rooms to come on line in the future, a low-spill phased array is needed, along with the expensive requirement of cutting the concrete floors for the wire, the installed system cost escalated from $3,002.00 to $11,731.20 – over four (4) times the simple system pricing.

There are obviously many variables between these two examples in essentially the same space. For example, there may be only a small amount of metal loss and no need to control spill which would reduce the price by not requiring phased array type equipment but only a slightly more

powerful loop driver. Concrete cutting and filling are expensive and not technically of any advantage to the loop system, one way or another. If this work can be avoided, significant savings can be made on the overall installation.

As you work more and more with AFILS (Audio Frequency Induction Loop Systems) you will gain experience in estimating and anticipating the costs and complexities of the systems and in helping and guiding customer’s choices.

Professionals with experience in hearing loops can do a good job of estimating the cost once a test loop or, loops have been completed. It is crucial to always test for magnetic background noise in the proposed space, and then perform test loops and you will be assured you’re

heading down the right path. Also, it is extremely important for you to provide all of the requested data on our Listen Technologies Hearing Loop System Clarification Form, along with any AutoCAD drawings, etc. for us to make a proper recommendation or, design.

Please let us know how we can assist you in a successful Hearing Loop installation.

For additional information contact:

Listen Technologies Corporation

+1.801.233.8992

1.800.330.0891

Stay Informed

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.